Description

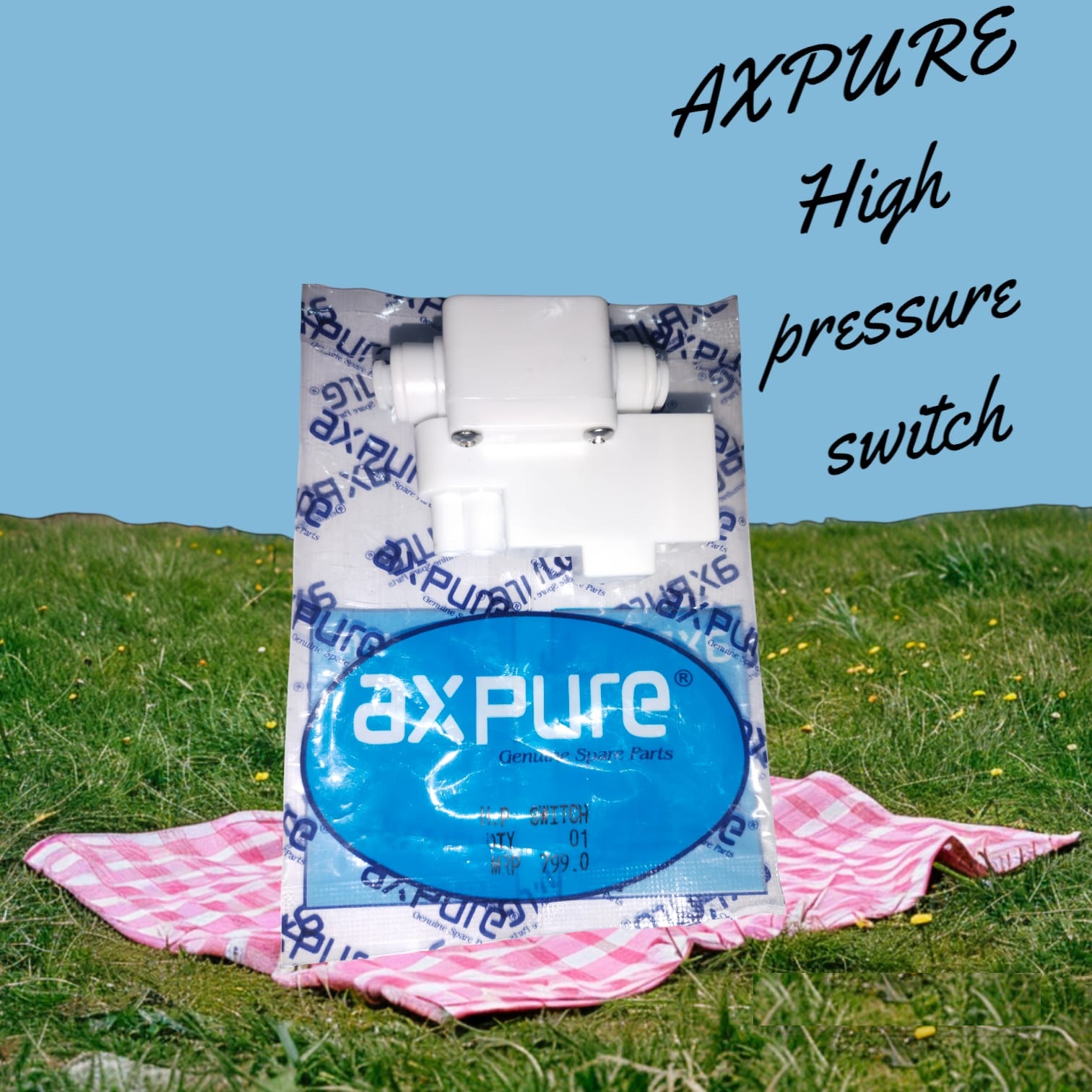

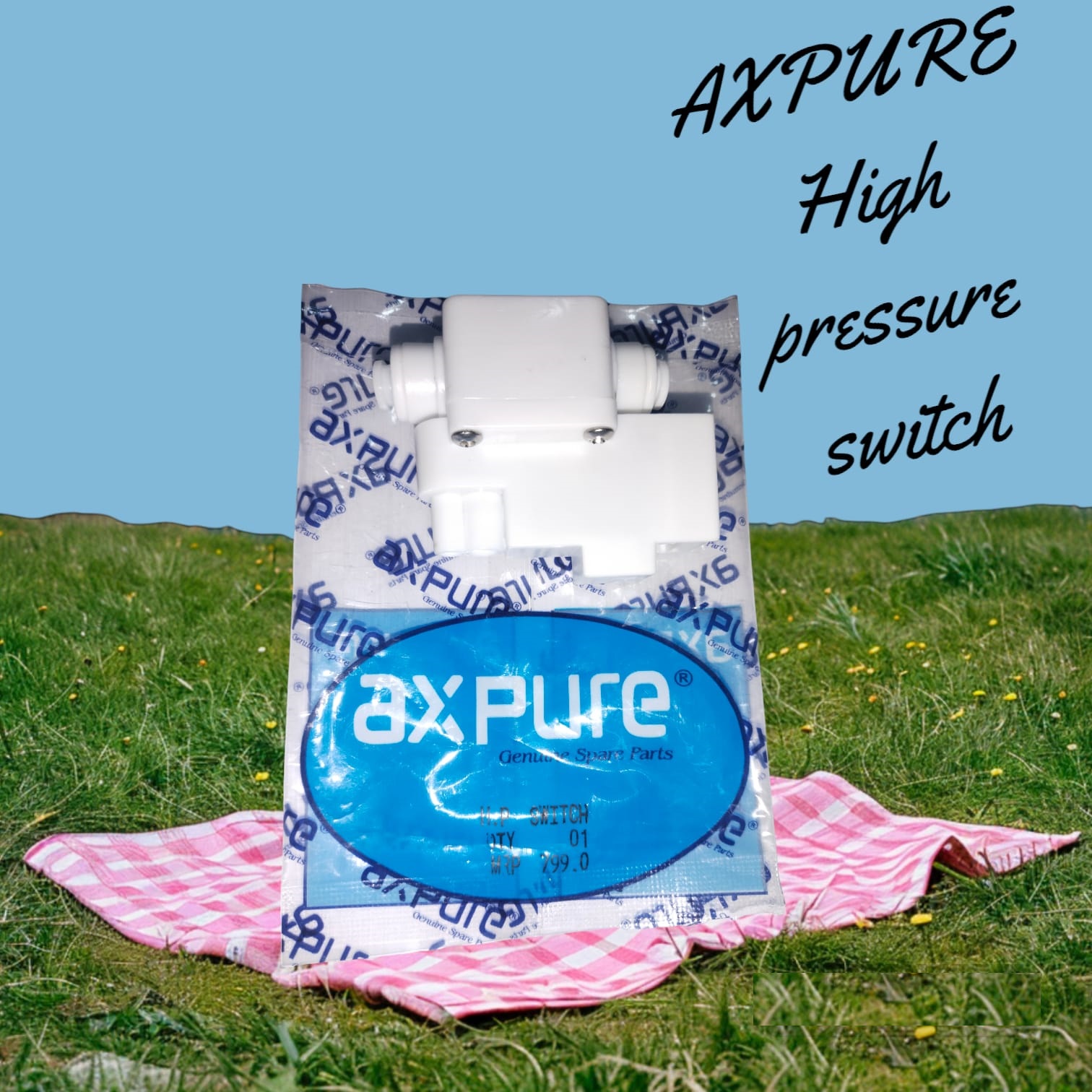

he most common form of high pressure switch is diaphragm activated, which is actuated by pressure changes. As with all diaphragm pressure switches, actuation is triggered when the flow exceeds the set point.

A furnace pressure switch is an automatic safety feature located near the motor. It shuts the furnace down if it senses negative pressure created by the draft inducer motor. This protects your home from dangerous backdrafting, which is when exhaust fumes are reintroduced into the system.

High pressure switch mounted at the exit of the booster pump to cut osmosis water under high pressure. It cuts the water supply prior to filtration. It acts like an automatic switch when installed on a 24V solenoid valve.

A pressure switch is a device that opens or closes a set of contacts when a certain pressure is applied to the diaphragm of the switch, thus protecting the system from excessively high or low pressures. A high-pressure switch is connected to the discharge, or “high” side of the system to sense discharge pressure.

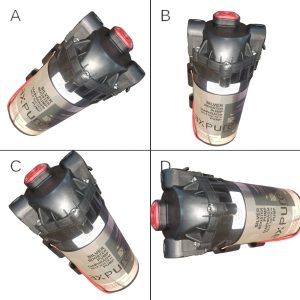

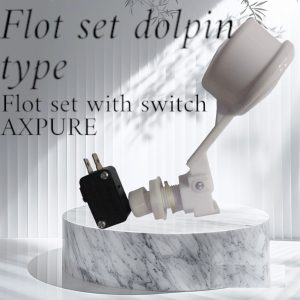

If tank pressure is high, the water coming from the filters won’t enter the RO holding tank. To pressurize an RO tank, drain all water from the tank and then use a bicycle pump to bring pressure to 7-9 psi. RO pressure tanks can wear out with time, so if the tank bladder is ruptured, the tank will need to be replaced.

After removing all the water from the tank, use a pressure gauge to determine the pressure in the tank. If low, add air with a pump until you have 7-8 psi. Be careful to only add a small amount of air at a time, as too much pressure can rupture the air bladder.